Why digital radiography may be a better solution than film

Industrial radiography has been an essential tool in various industrial applications for decades, providing crucial information about the internal structure and integrity of various materials and components. However, the traditional method of film radiography will gradually be replaced by digital radiography (DR) due to its numerous advantages. In this article, we will explore the benefits of DR over traditional film radiography and why it will become the industry norm.

Increased Speed and Efficiency

DR eliminates the need for film processing, which can take several hours at the end of a site visit and can be time-consuming. With digital radiography, images can be acquired, processed, and analysed in a matter of seconds, allowing for quick and efficient inspection and reporting. This increased speed allows for a more streamlined workflow, reducing downtime and improving overall productivity with the added addition of reduced exposure times and strength of isotope required.

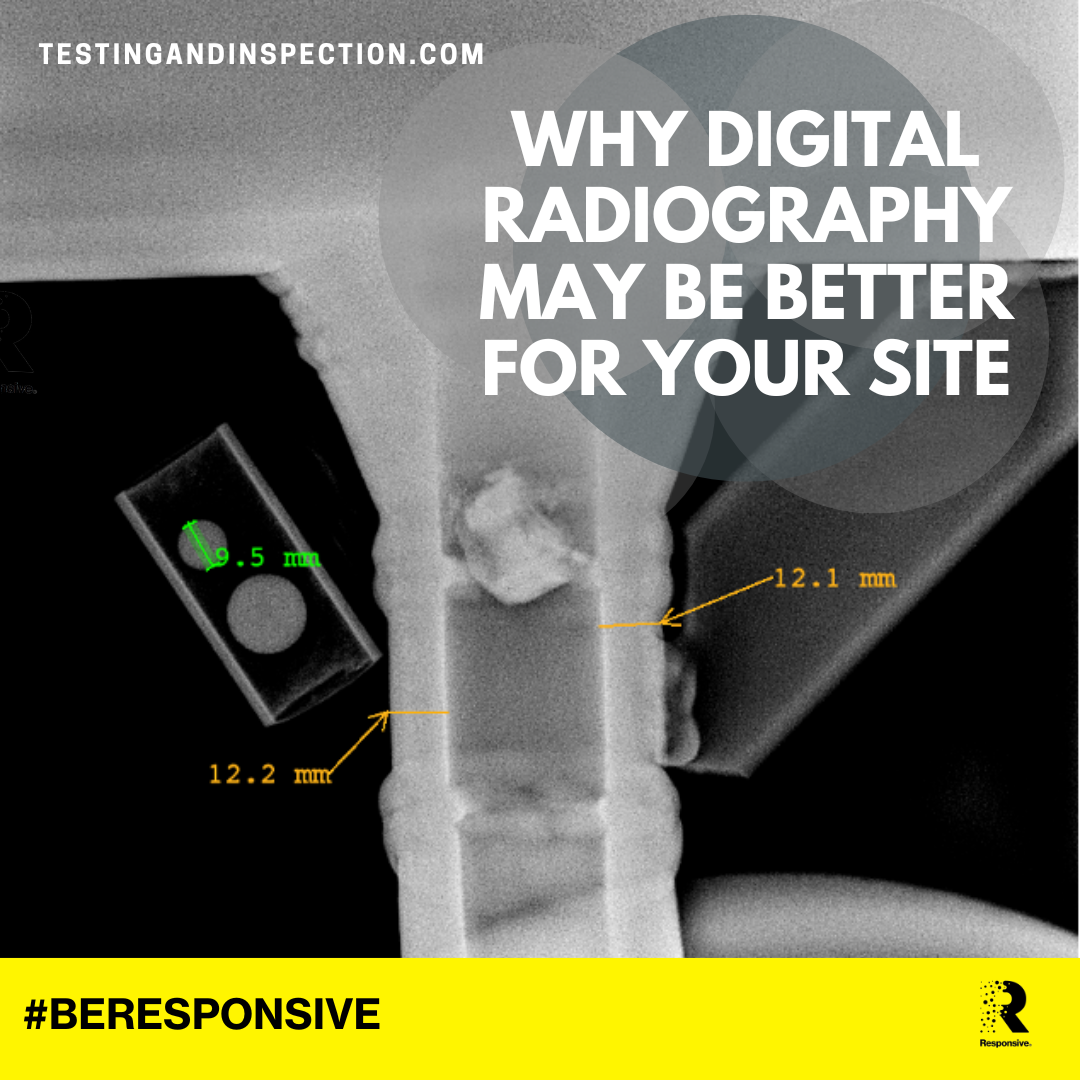

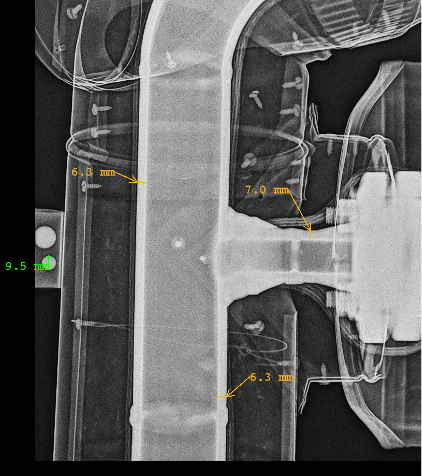

Improved Image Quality DR images are of much higher quality compared to traditional film radiography, as they are captured and processed electronically. Digital images are much clearer and have a higher resolution, which makes it easier to identify and analyse defects and flaws. In addition, DR images can be manipulated and adjusted to enhance the image quality, making it easier to see important details, all whilst retaining its original image as a separate file for audit purposes.

Increased Flexibility

DR images can be easily stored, retrieved, and shared electronically, which makes it easier to work with the images and share information with others. This increased flexibility allows for more effective collaboration and reduces the need for physical film storage. Additionally, IDR images can be remotely accessed from anywhere, making it easier to review and analyse images from a remote location.

Enhanced Safety

Radiography requires the handling and storing of radioactive isotopes, which can pose a health and safety risk to workers. DR reduces this risk, as the exposure times are drastically reduced. This even allows for smaller isotopes to be used vs material thickness/density.

Cost Savings

DR eliminates the need for film processing and storage, which can be expensive over time. In addition, the increased speed and efficiency of DR result in reduced downtime and improved productivity, saving time and money. Furthermore, the longer lifespan of digital images compared to film images means that DR is a more cost-effective option in the long term.

Environment Digital radiography does not require chemical processing. So, no requirement for Fixer or Developer and no requirement to dispose of the chemicals in an environmentally friendly manner.

In conclusion, industrial digital radiography offers numerous advantages over traditional film radiography, including increased speed and efficiency, improved image quality, increased flexibility, enhanced safety, and cost savings. The benefits of DR make it the preferred choice for many industries, as it provides a more effective and efficient solution for industrial radiography

Book Responsive for Site Radiation Works Below